My research revolves around tribology, the science of surfaces. I am particularly interested in the modeling of rough contact interfaces and how understanding these interfaces can help modeling friction and wear of solids.

For a complete list of publications, see my publications list.

Rough contact interfaces

Virtually all real surfaces (from geological fault faces to hard drives, from roads to cartilage) are rough if one looks closely enough. This means that contact between two solids is never perfect, or even smooth: the solids only touch in sparse areas with complex geometries. The “true contact area” is typically only a few percent of the apparent area of contact (the macroscopic dimensions of the solids), and it is from the surface interactions at this “true contact area” that properties like friction and wear emerge (see nanoscale tribology below).

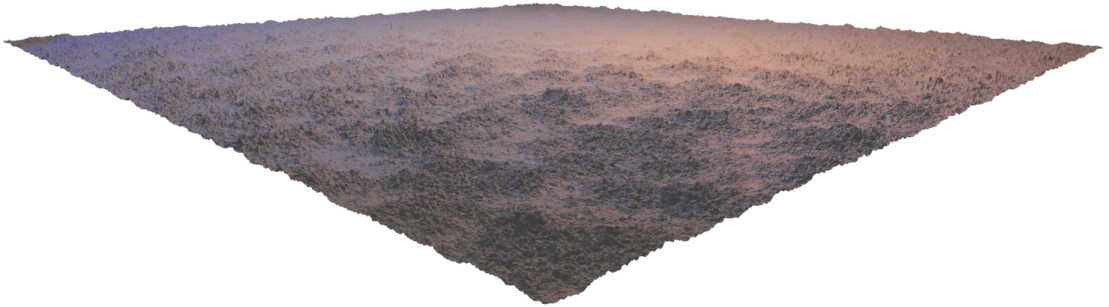

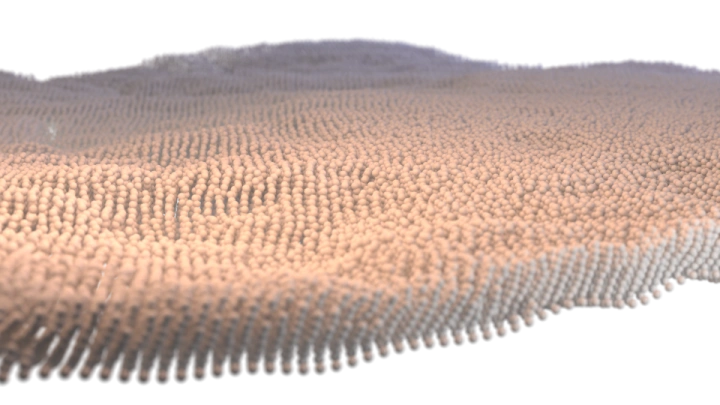

Many natural surfaces exhibit a fractal-like behavior: as one “zooms-in” on roughness, one discovers more roughness at smaller scales.

A "fractal" rough surface, rendered with Blender

The fact that surface roughness does not have a characteristic scale makes contact interfaces challenging to model, because all roughness scales can be relevant and should be accounted for. Things become even more complex when non-linear material behavior comes into play.

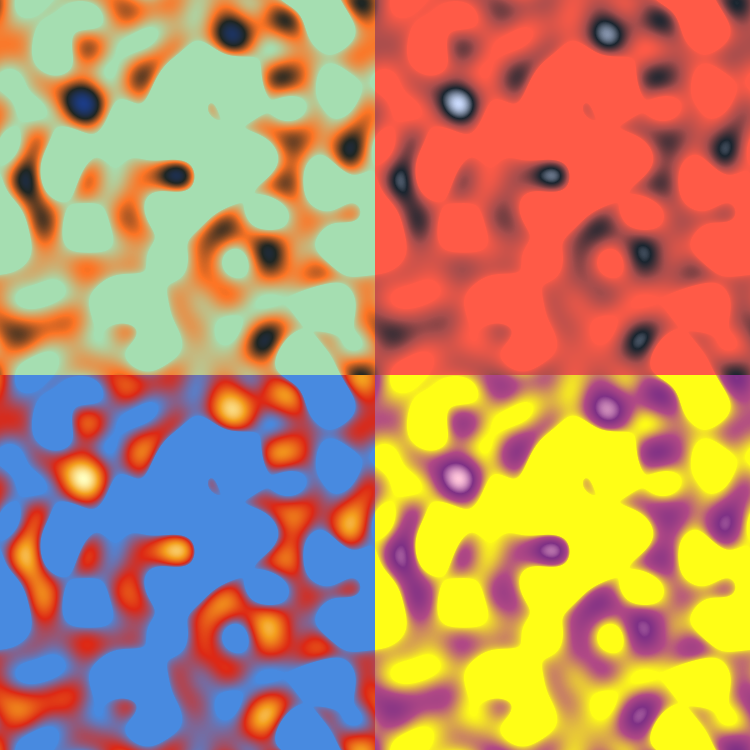

During my doctoral work, I have developed an efficient numerical method to model contact of rough surfaces with elastic-plastic materials (such as metals). Below is a picture of such a simulation, where we can see the plastic zones that develop due to the heterogeneous contact pressure.

Distribution of plastic zones below asperties in contact, computed with Tamaas, rendered with Paraview

Such simulations are possible thanks to the use of Fourier-domain Green’s functions that I derived (cf. The Mindlin Fundamental Solution - A Fourier Approach). I have implemented this Fourier-based numerical method for elastic-plastic contact in an open-source code called Tamaas, which is a hybrid C++/Python library for simulating all sorts of contact situations. Feel free to check out the tutorials.

Nanoscale tribology

Friction is a phenomenon that takes root in the many, both in kind and in number, molecular interactions that occur when two surfaces are close enough. However, these interactions are greatly influenced by the inevitably present roughness of these surfaces, and by the long distance dialog between micro-contact junctions that takes place through the medium of bulk interactions. This distortion of the molecular picture explains in part why macroscopic friction models, like Amontons–Coulomb friction or the more general “rate-and-state” friction, remain empirical. With energy efficiency being a foremost societal focus in the face of climate change, predictive friction models could provide a boon to design surfaces that greatly reduce friction losses.

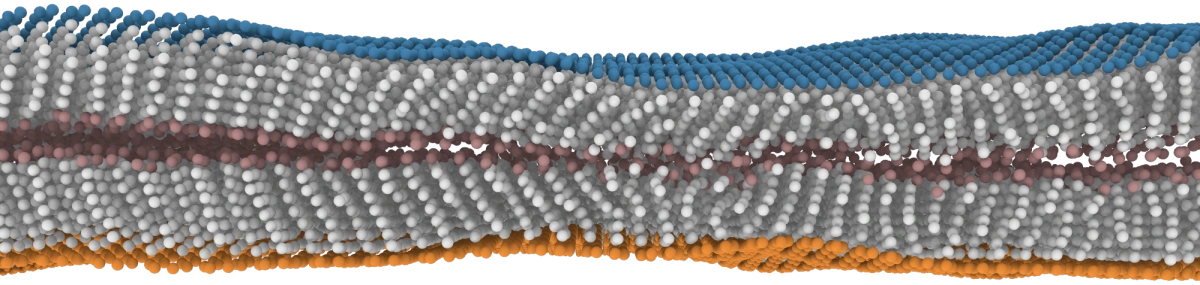

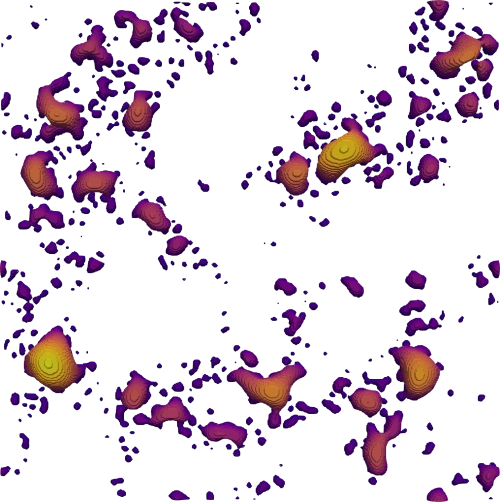

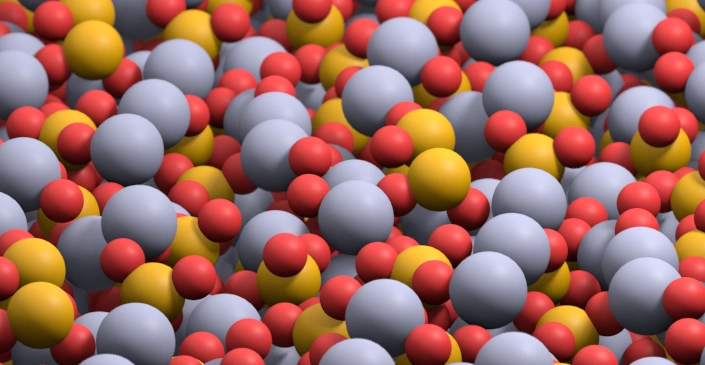

My research at molecular scale aims to lift the veil on the mechanisms that occur at the nano-scale, interact with the roughness and greatly influence the macroscopic friction and wear response. For this, I use molecular dynamics to describe the objects in contact and the interactions between surfaces that are rough at the nanoscale. During my two postdocs, I have studied the friction behavior of fatty acid monolayers adsorbed on rough surfaces and how molecular interaction within contact jonctions can explain the transient friction behavior observed in experiments, and contact properties of heterogeneous zinc-polyphosphate tribofilms.

Fatty acid monolayer adsorbed on a nanometrically rough surface, rendered with Blender

Zinc-phosphate tribofilm, rendered with Blender

Scientific Communication

I believe proper scientific communication, targeted at peers but also at the greater public, is an important part of a researcher’s work. To create figures that appeal to the people outside the scientific field, I use cutting edge (open-source) tools like Blender. I recently made a render from roughness measured on a nanoscrystalline diamond surface by Luke A. Thimons and co-workers (doi:10.57703/ce-4r74d), which was used in a press release for the Contact.Engineering open platform, whose goal it is to standardize rough surface analysis, facilitize that analysis and the open sharing of data, in the spirit of reproducibility.

Nanocrystalline diamond surface, rendered with Blender

I also believe visuals are the opportunity for science to meet art, and artistically appealing visuals can be the start of a scientific conversation.